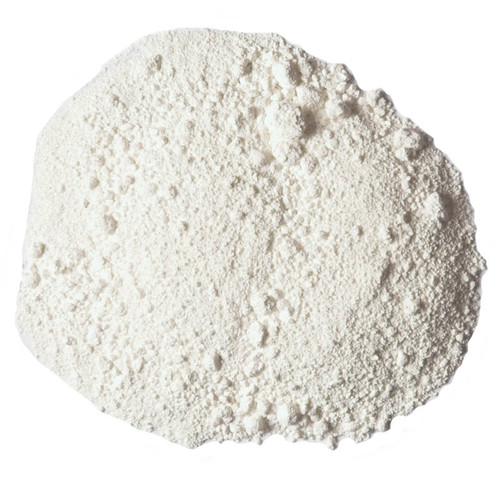

Polyacrylamide (PAM) is one of the most important industrial polymers and is used in numerous industries, including water treatment, oil and gas, agriculture, paper and textile industries. This polymer is of particular interest due to its unique properties such as gelation, viscosity and coagulation. The production of polyacrylamide powder requires a complex process that must be carefully carried out to achieve a high-quality final product. This article describes processes for the production of polyacrylamide powder.

Commodities

Acrylamidmonomer

Acrylamide monomer is one of the main raw materials for the production of polyacrylamide.Acrylamide is a colorless, crystalline chemical substance and the main raw material in its production.

Motivator

Various catalysts such as peroxides, azo compounds and photocatalysts are used to initiate the polymerization process. These catalysts play an important role in the speed and efficiency of polymerization .

Solvent

Some production processes use solvents such as water, alcohol, and organic solvents to dissolve monomers and catalysts. Solvents play an important role in controlling the quality of the reaction and the final product.

Production

Block copolymerization

In this process, acrylamide monomers are polymerized in pure form without solvents. The polymerization reaction takes place under the influence of a catalyst and temperature. The result of the reaction is a polyacrylamide block, which is then ground into powder.

Vergangenheit

- Vorbereitung der Rohstoffe : Mischen von Acrylamidmonomer mit Katalysator.

- Einleitung der Polymerisation : Die Mischung aus Monomeren und Katalysator wird unter Bedingungen gebracht, die für die Einleitung der Polymerisationsreaktion geeignet sind.

- Reaktionsende : Nach Abschluss der Reaktion werden Polyacrylamidblöcke erhalten.

- Trocknen und Mahlen : Polyacrylamid wird getrocknet und dann zu Pulver gemahlen.

Lösungspolymerisation

Bei dieser Methode wird Acrylamidmonomer in einem Lösungsmittel gelöst und mithilfe eines Katalysators polymerisiert. Durch diese Reaktion entsteht Polyacrylamid in Lösung, das anschließend getrocknet und zu Pulver verarbeitet wird.

Past

- Dissolving the monomer : Dissolve the acrylamide monomer in a solvent such as water or alcohol.

- Catalyst addition : A suitable catalyst is added to the monomer solution.

- Initiation of polymerization reaction : Bring the monomer and catalyst solution under conditions suitable for initiating the polymerization reaction.

- End of reaction : After completion of the reaction , a polyacrylamide solution is obtained.

- Drying and grinding : The polyacrylamide solution is dried and then ground into powder.

Suspension polymerization

In this process, acrylamide molecules are polymerized in a non-polar medium, such as oil, and the molecules are suspended in the medium in the form of small droplets and then polymerized by a catalyst. Once the reaction is complete, polyacrylamide is formed in the form of small particles, which are then dried and processed into powder.

Past

- Monomer Suspension : Acrylamide monomer is suspended in the form of fine droplets in a non-polar medium.

- Catalyst addition : A suitable catalyst is added to the monomer suspension.

- Initiation of polymerization : The monomer and catalyst suspension is placed under conditions suitable for the initiation of the polymerization reaction.

- End of Reaction : After completion of the reaction, fine polyacrylamide particles are obtained.

- Drying and grinding : Polyacrylamide granules are dried and then ground into powder.

Application of Polyacrylamide Powder

Water treatment

Polyacrylamide powder is widely used in water treatment processes. It is an effective coagulant and flocculant that can separate suspended particles and organic matter from the water.

Oil & Gas Industry

In the oil and gas industry, polyacrylamide powder is used as an additiveto increase viscosity and reduce friction when drilling oil and gas wells. This substance helps to increase the efficiency and productivity of drilling.

Agriculture

Polyacrylamide powder is used .in agriculture as a water storage agent and soil erosion inhibitor, it helps improve soil structure and increase water permeability.

Papermaking

In the paper industry, polyacrylamide powder is used as a binder and paper strength enhancer. This substance improves the quality and physical properties of paper.

Textile industry

Polyacrylamide powder is used in the textile industry as a dye and fabric improver. This substance helps to increase the durability of the paint and improve the quality of the fabrics.

Advantages of Polyacrylamide Powder Production

High efficiency

Polyacrylamide powder is excellent for transporting and distributing liquids and materials due to its unique properties. This material helps to increase the accuracy and efficiency of various processes.

Corrosion and chemical resistance

Polyacrylamide powder has high corrosion and chemical resistance. This property helps to extend the life of the product and reduce the need for repair and maintenance.

Strength and durability

Polyacrylamide powders offer high strength and durability and help improve the efficiency and performance of your system.

Flexibility

Polyacrylamide powder provides flexibility, allowing the membrane to perform well under a variety of operating conditions and prevent failures.

Easy to install and maintain.

Thanks to its simple structure and high-quality materials, polyacrylamide powder is easy to install and maintain, which helps reduce operating costs and extend service life.

At last

Polyacrylamide powder is of great importance due to its unique properties and wide application in production. The use of high-quality raw materials and precise production methods enables the production of high-quality and effective polyacrylamide powder. This material helps to optimize various processes and reduce operating costs. It is a necessary and important material in all areas of life.