Laundry detergent is one of the most common everyday cleaning products and helps keep clothes clean and hygienic. Its production is a complex industrial process that combines chemistry, engineering, and materials science. In this article, we examine the production stages, raw materials, and technologies of laundry detergents, as well as important aspects of the detergent industry .

Raw materials for the production of washing powders

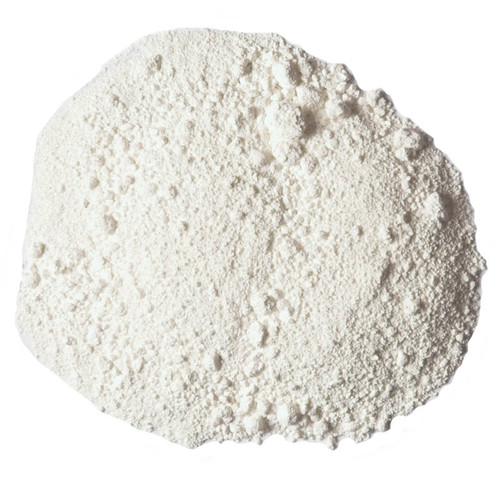

The production of washing powders begins with the selection of high-quality raw materials. The most important ingredients include:

-

Surfactants (activated surfactants)

are the main cleaning agents in detergents and play an important role in removing grease and stains. -

Bleach and enzymes:

These substances are added to the powder to increase its cleaning power and remove stubborn stains such as grease and protein. -

Abrasives:

These materials help to remove surface stains and improve mechanical cleaning performance. -

Polymers and release agents are used

to prevent the powder particles from sticking together and to ensure free flow during filling and cleaning. -

Fragrance and color: To increase the attractiveness of the product and customer satisfaction, detergents are manufactured with the desired fragrance and color

. -

Additional additives

such as plasticizers, color stabilizers and stain protectants improve the quality of the final product.

Phases of washing powder production

The production of washing powders involves several main steps, which are carried out in factories with industrial facilities:

1. Preparation of raw materials

In this phase, materials such as surfactants, bleaching agents, enzymes, and abrasives are weighed and prepared according to the product specifications. The precise dosage of each individual ingredient is crucial, as it directly affects the quality of the final product.

2. Mix and stir the ingredients.

The raw materials are placed in an industrial mixer and mixed until a homogeneous mixture is achieved. This ensures an even distribution of the active ingredients and prevents them from clumping into powder.

3. Chemical reaction step (optional)

In some formulations, chemical reactions take place during this phase, such as the formation of enzymes or the activation of bleaching agents. These reactions must be carefully controlled to ensure optimal performance of the final product.

4. Drying

After mixing the ingredients, some processes require moisture removal . Drying is typically done with a spray dryer or an industrial dryer to obtain a dry, uniform powder.

5. Crushing and Granulating

The dry powder is placed in a mill and ground to a standard size. The correct granulation ensures that the powder dissolves quickly in water and prevents clumping.

6. Add release agent and spices.

At this stage, separating agents and flavorings are added to the powder, and the finished mixture is stirred to ensure that all ingredients are evenly distributed.

7. Quality control

After sampling, the quality of the finished powder is analyzed, including its cleaning effect, water solubility, odor, color, and particle size. Strict quality control is essential, as any problems at this stage can lead to a product recall.

8. Packaging

Once the detergent meets the quality standards, it is transferred to the packaging machine. The packaging can consist of plastic bags, cardboard boxes, or sealed pouches. Besides protecting the product, good packaging is a marketing tool that ensures customer satisfaction.

Transfer of proteins from polyacrylamide gels

Important points in the production of washing powders

-

Precautions when handling chemicals: Some raw materials, such as bleach and enzymes, can cause skin irritation and respiratory problems. Personal protective equipment must be worn and adequate ventilation of the facility must be ensured.

-

Precise formulation:

Any changes to the quantities of raw materials used can impair the quality and effectiveness of the cleaning powder . Therefore, a precise formulation and laboratory tests are essential before mass production. -

Controlling humidity and temperature is crucial.

They affect powder quality and prevent clumping. Precise control of these parameters is therefore essential during the production process. -

Environmental hygiene standards in the manufacture of detergents must

meet industry-standard hygiene standards to ensure consumer health. -

Improving energy and raw material consumption

through the use of modern technologies, optimizing processes , reducing costs and increasing production efficiency.

Types of washing powders

The production of washing powders also varies depending on the intended use and product properties:

-

This hand washing powder

was specially developed for hand washing and is characterized by strong cleaning power and rich lather. -

A washing powder

suitable for washing machines. It foams in a controlled manner and will not damage your washing machine. -

Special detergents.

Some detergents are specially designed for washing colored, baby, or delicate laundry and contain special enzymes and preservatives.

In conclusion

The production of laundry detergent is a complex industrial process requiring expertise in chemistry, engineering, and materials science. Key production steps include raw material preparation , mixing, chemical reactions, drying, milling, additive addition, quality control, and packaging.

Focusing on the quality of raw materials, precise formulation, control of process conditions and compliance with hygiene regulations are key factors in the production of high-quality and competitive washing powders.

Laundry detergent is more than just an everyday consumer product; its production process also represents a model that integrates science, technology and industrial engineering to provide consumers with high-quality and effective products.